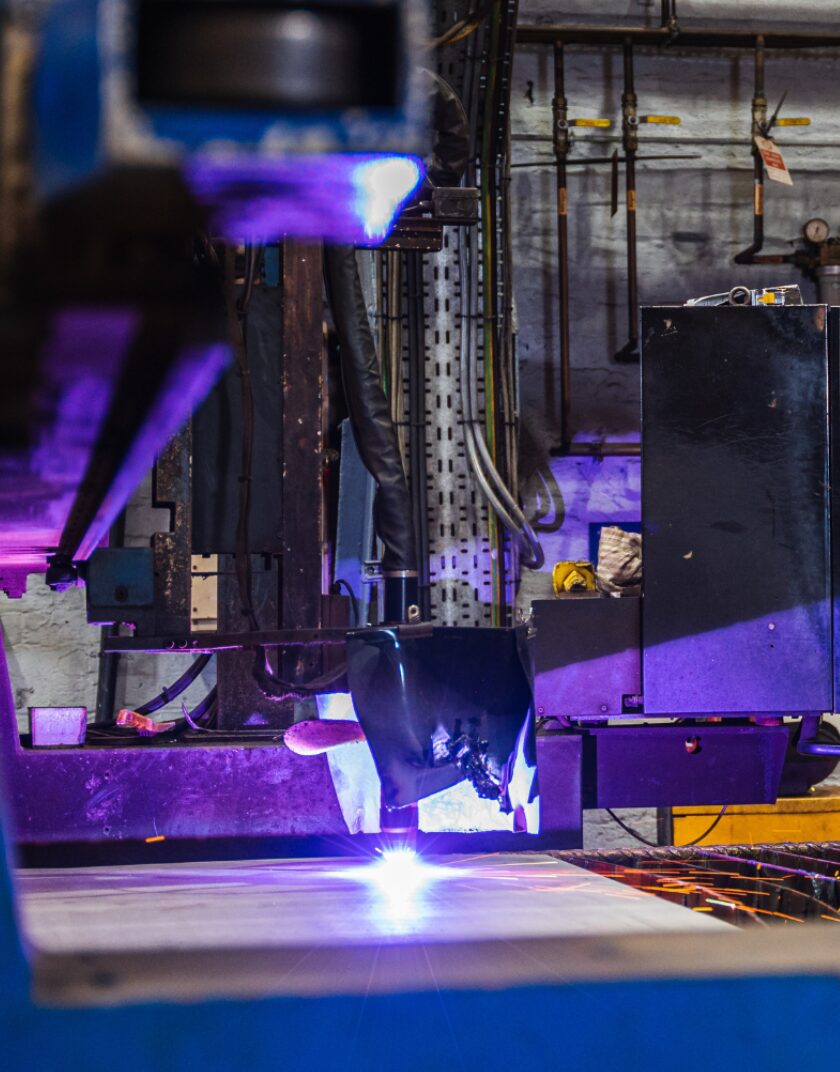

Our plate cutting services

Advantages of Brown McFarlane’s Plate Cutting Services

Advantages of Brown McFarlane’s Plate Cutting Services

- Precision and Accuracy: We prioritise delivering clean, dimensionally accurate cuts, minimising material waste and ensuring a seamless fit for your project.

- Efficiency and Speed: Our advanced equipment and experienced operators guarantee efficient plate cutting, keeping your project on schedule.

- Customisable Solutions: We can accommodate a wide range of plate thicknesses and cutting requirements, tailoring our services to your specific needs.

- Extensive Material Selection: Access a vast inventory of high-quality steel plates from leading European manufacturers.

- Expertise Across Industries: We have extensive experience serving various crucial market sectors, including construction, nuclear and wind energy.

- Integrated Steel Processing: Combine plate cutting with our other processing services, such as bending, forming, and machining, for a complete solution.