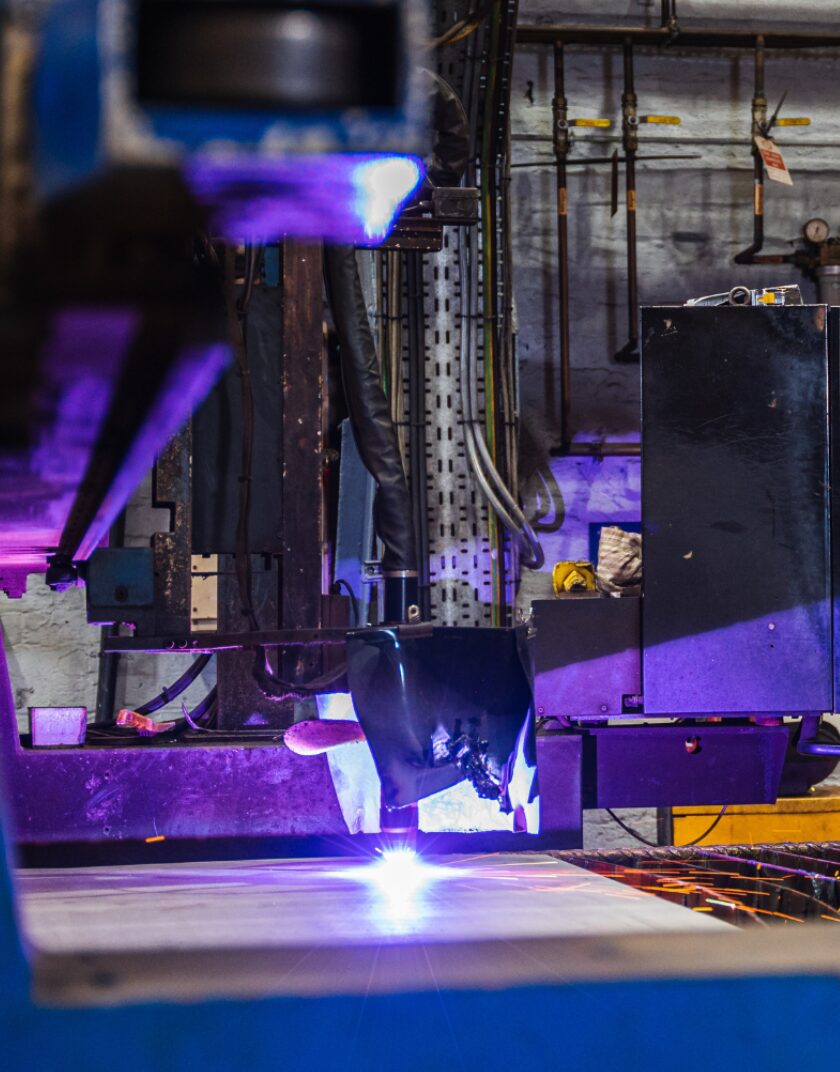

Advantages of plasma cut steel:

- Fastest order turn around of all plate cutting services.

- Angular deviations are reduced resulting in improved quality of the cut surface.

- Plasma cutting has the capacity to internally produce 1:1 ratio holes and slots between 5 and 25mm

- Significant improvement in cut quality and contour accuracy on inner and outer contours and True Hole processes

- Eliminates the need for any drilling or machining

- Cuts at lower temperatures reducing heat affected zones and improving cut quality. This makes plasma cutting ideal for intricate designs

More information

Our range of plasma machines are fully supported by the latest CAD technology and our team of dedicated CAD technicians ensure we delight our customers with accurate and precise plasma cut parts.

Capabilities of Brown McFarlane’s Plasma Cutting Services:

| Dimension | Capability |

|---|---|

| Thickness | Up to 45mm – depending on end use |

| Width | up to 4 metres |

| Length | up to 24 metres |