Here at Brown McFarlane, we are the company is able to offer some of the best steel profiling services in the world from our state-of-the-art processing centre in Stoke-On-Trent.

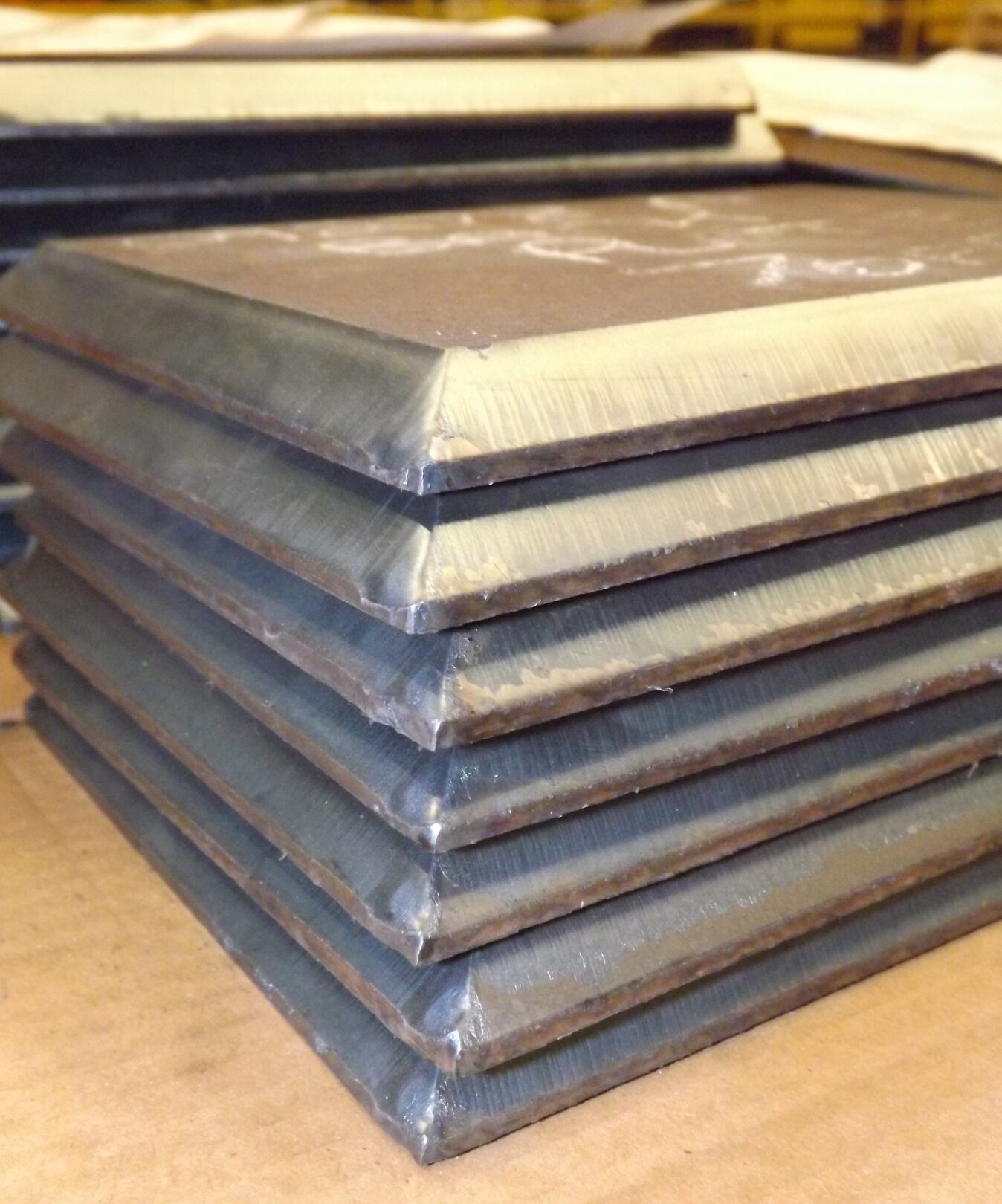

We offer numerous steel profiling options from oxy propane gas and high definition plasma, to water jet cutting. The available profiling equipment enables us to cut the largest plate dimensions to size, in thicknesses up to 400mm and weights up to 30 tonnes.

The Infinity skew plasma cutting head technology ensures we continue our mission to make the latest profiling methods readily available to our customers. This strengthens our ability to support both the highest quality standards and further improve our very short delivery times from order. Working with our team of quality assured subcontractors we can provide you with parts ready for final assembly. One order and a single point of contact at Brown McFarlane take the problem from your desk and provide you with a complete supply chain.

Brown McFarlane prides itself on being able to help its customers. Whatever your requirement for processed plate, our range of plate profiling cutting equipment ensures we can offer exactly what you require. Click below to make an enquiry today