Abrasion resistant steel is an essential material for industries that deal with extreme wear and tear, such as mining, construction and engineering.

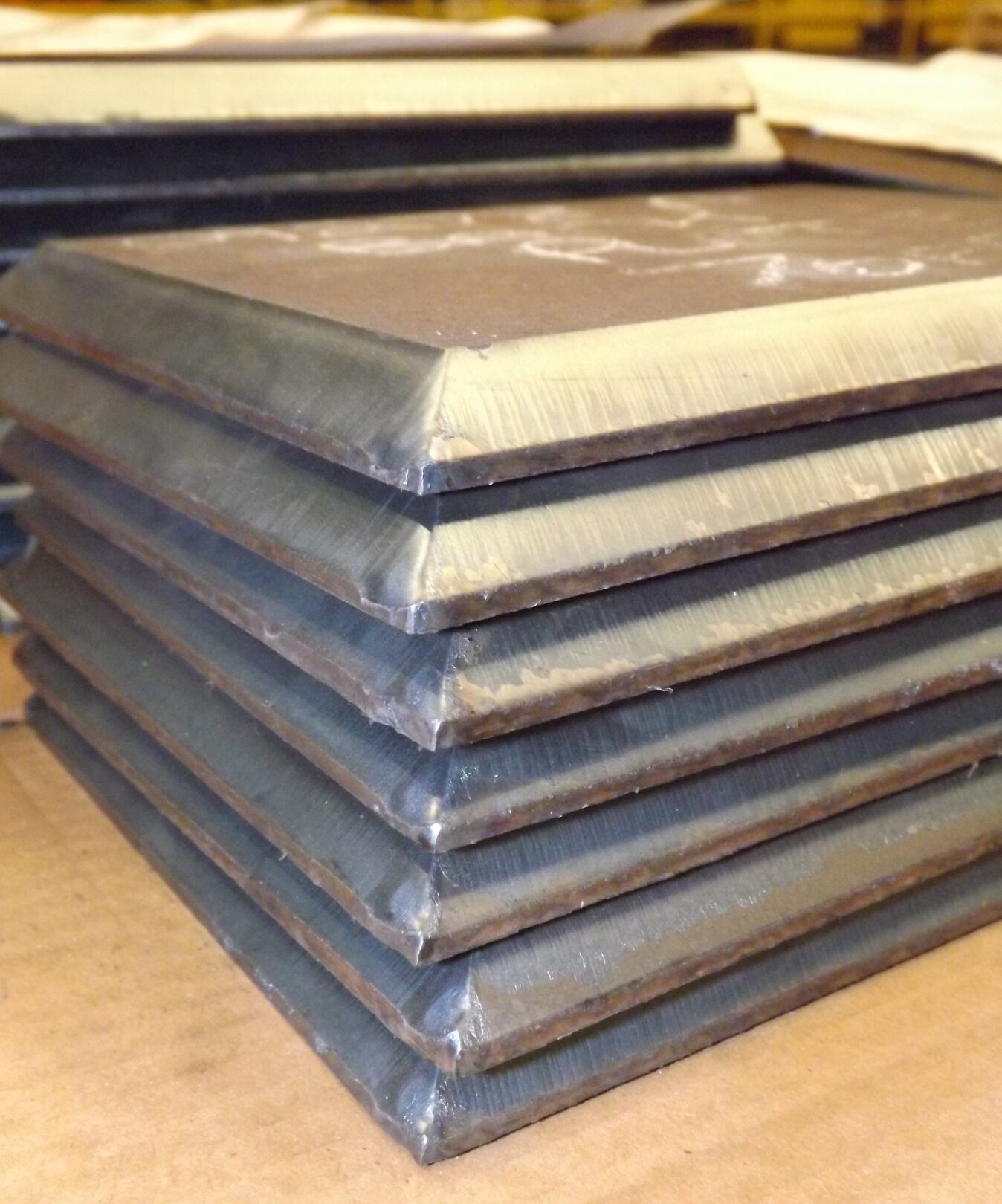

Specifically designed for exceptional durability, these robust steel plates are designed to withstand harsh conditions, including heavy impacts, friction and extreme pressures. Their ability to perform reliably in the toughest environments not only helps extend the lifespan of equipment and infrastructure, but also reduces maintenance requirements and lowers overall operational costs.

However, as is the case with many of the specialised steel plates stocks by Brown McFarlane, abrasion resistant steel isn’t one size fits all when it comes to selecting the perfect material for your individual applications. To account for the varying requirements of this material, we stock a wide selection of abrasion resistant steel grades, each carefully engineered with their own unique properties.

By understanding these properties, you can significantly enhance your project’s efficiency with the assurance that you have the ideal grade for your requirements.

What is Abrasion Resistant Steel?

Abrasion resistant steel is a high performance material specifically designed to withstand wear, impact and sliding contact far more effectively than standard steel grades. This durability makes it an essential material for industries like mining, construction, heavy machinery and renewable energy where equipment is exposed to harsh conditions and constant friction.

The steel’s exceptional resilience is achieved through a carefully engineered chemical composition, with high levels of carbon and other alloying elements, combined with advanced heat treatment processes that enhance its hardness and toughness.

The superior performance of abrasion resistant steel is driven by two fundamental factors:

- High Hardness Levels

Through water or oil quenching processes, these steels achieve significant hardness that dramatically increases resistance to wear and tear from abrasion, impact and sliding contact.

- Optimised Chemical Composition

The steel features carefully balanced elements including carbon, chromium and manganese that bolster resilience against both physical and chemical wear.

What Makes Steel Abrasion Resistant?

Several key factors influence the abrasion resistance of steel:

- Hardness: Measured in Brinell Hardness (HBW), higher values indicate superior resistance to wear and deformation.

- Alloy Composition: Elements such as chromium, nickel, molybdenum and titanium significantly enhance wear resistance.

- Heat Treatment: Processes like quenching and tempering refine the steel’s microstructure to maximise durability.

- Carbon Content: Properly balanced carbon levels ensure an optimal blend of hardness and toughness.

Together, these factors determine steel’s ability to withstand abrasive forces, making them critical considerations in material selection and processing.

Common Types of Abrasion Resistant Steel

Understanding the various grades available helps you make an informed decision when selecting the ideal material for your specific application. At Brown McFarlane, we offer a wide range of grades, each with unique properties to ensure you achieve the best performance, durability, and efficiency for your needs.

Abrasion Resistant Steel Specifications

- Quard 400 (400 HBW): Offers excellent wear resistance with good weldability and formability. Ideal for moderate abrasion applications.

- Quard 450 (450 HBW): Provides increased hardness whilst maintaining reasonable fabrication properties. Suitable for higher impact applications.

- Quard 500 (500 HBW): Delivers maximum wear resistance for the most demanding environments, though with reduced formability.

Creusabro® Abrasion Resistant Steel

- Creusabro® 4800: Engineered with advanced alloying elements including chromium, nickel, molybdenum and titanium. Provides wear resistance 50% higher than conventional 400HB water-quenched steel.

- Creusabro® 8000: Offers exceptional performance with wear resistance up to 50% better than standard 500HB steel, whilst maintaining excellent weldability and workability.

The Creusabro® range delivers superior wear resistance compared to conventional water quenched steels, with advanced alloying elements enhancing durability, weldability and workability.

Applications Across Industries

Mining and Quarrying

- Digger Buckets

- Crusher Components

- Wear Liners

- Conveyor Systems

Construction and Demolition

- Bulldozer Blades

- Grader Surfaces

- Demolition Equipment

- Tipper Bodies

Agriculture

- Plough Shares

- Harvester Blades

- Tilling Equipment

- Seed Drills

Energy and Recycling

- Shredder Components

- Boiler Components

- Waste Processing Equipment

- Renewable Energy Systems

Partnering with Brown McFarlane

Brown McFarlane is a trusted specialist in steel plate distribution, offering high-quality, tailored solutions for all steel plate needs. With decades of experience, we pride ourselves on delivering exceptional services, expert advice and a comprehensive range of steel plates to meet the demands of various industries, including the most heavy duty applications.

Whether you require standard Quard grades or Creusabro® materials (including the recently added Creusabro® 6400 grade) , our experienced team provides the technical knowledge and material quality essential for your project’s success.

Contact Brown McFarlane today to discuss your specific requirements and discover how our products, plate processing services and industry expertise can enhance your equipment’s performance and longevity.

Related News

Weathering Steel Explained: Grades, Benefits & Applications