Building in the ocean is one of engineering’s greatest challenges. Structures must withstand relentless saltwater, punishing wave loads and extreme weather while maintaining structural integrity for decades. The single most critical decision in such projects lies in the construction material – steel. Selecting the correct offshore steel plate is a decision based on safety, longevity and project success.

In this guide, we provide a practical overview of marine steel grades, key selection criteria, and how to navigate the complex standards governing these materials.

What is Marine Grade Steel?

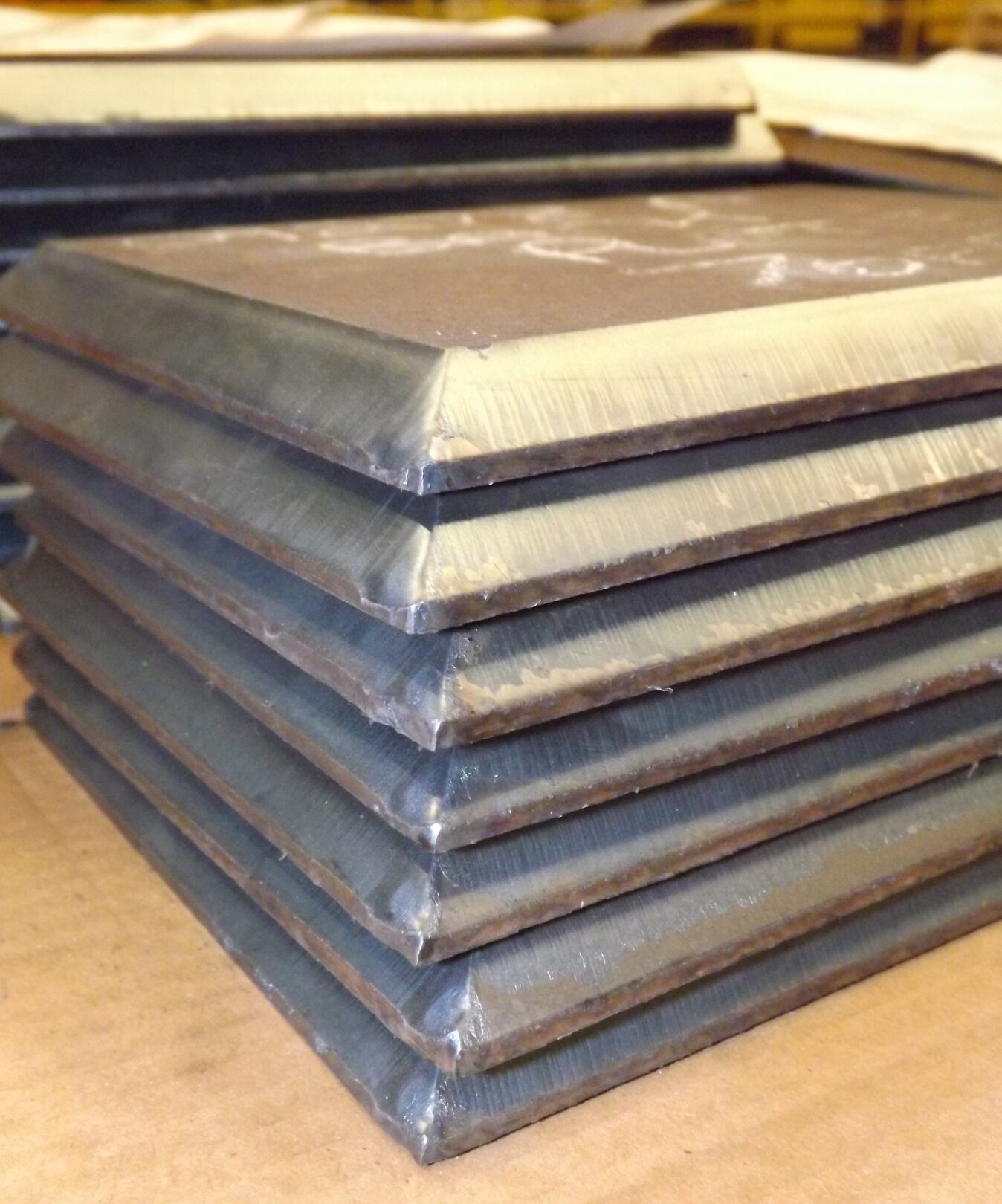

Marine-grade steel is specifically formulated to resist the unique deterioration caused by marine environments. It’s not a single grade, but a category defined by enhanced properties:

- Corrosion Resistance – Enhanced ability to resist pitting and general corrosion from saltwater and atmospheric salinity.

- Toughness – High impact resistance, particularly at low temperatures, to prevent brittle fracture.

- Weldability – Must be easily weldable without compromising its properties, crucial for large-scale fabrication.

- Strength-to-Weight Ratio – High yield strength to allow for robust structures without excessive weight.

These properties are achieved through careful control of chemical composition and rolling processes during manufacturing.

Best Steel for Offshore Structures

Identifying the best steel for offshore structures depends on the specific application, but common considerations include:

- Saltwater Exposure – Direct immersion, splash zones and atmospheric exposure each demand different protective measures or steel compositions.

- Dynamic Loading – Structures such as oil rigs and wind turbine foundations are subjected to cyclic loading from waves, requiring excellent fatigue resistance.

- Structural Criticality – Failure consequences are high, necessitating steels with proven fracture toughness.

Common applications and typical steel choices:

- Offshore Jackets & Platforms – High-strength, thick plates such as S355 grades and above, often with improved through-thickness (Z-direction) properties.

- Ship Hulls & Superstructures – Grades from shipbuilding standards or structural grades like S355, chosen for sections based on stress.

- Offshore Wind Monopiles & Transition Pieces – S355 is widely used, with S460 increasingly specified for higher strength in critical areas.

- Port & Harbour Infrastructure – A mix of standard structural steels and dedicated weather-resistant steel, which forms a stable rust patina to protect against atmospheric corrosion.

Offshore Steel Plate Grades Explained

European standard EN 10025 structural steels are prevalent in marine projects. Key grades include:

- S275 – A general-purpose structural steel with a minimum yield strength of 275 MPa.

- S355 – The most widely used grade for demanding applications, offering a minimum yield strength of 355 MPa and better overall toughness.

- S460 – Higher-strength steel used where weight reduction or extreme load-bearing capacity is vital.

Each grade is subdivided into subgrades (JR, J0, J2, K2), indicating their impact toughness at decreasing temperatures, a vital property for North Sea or Arctic operations.

Difference Between S275 and S355 for Marine Applications

Understanding the difference between S235 and S355 for marine use is fundamental to material selection.

| Property | S275 | S355 | Implication for Marine Use |

| Yield Strength | 275 MPa | 355 MPa | S355 allows for lighter sections or higher load-bearing capacity, crucial for reducing weight and material in large offshore structures. |

| Tensile Strength | Lower | Higher | S355 offers greater resistance to dynamic tensile stresses from waves and currents. |

| Corrosion Resistance | Similar (base material) | Similar (base material) | Neither is inherently stainless, and both require protective coatings. However, S355’s potential for thinner sections can influence coating system design. |

| Toughness & Weldability | Good | Typically Better | S355, especially in subgrades like J2 or K2, generally offers superior guaranteed impact toughness at lower temperatures. |

| Cost & Availability | Generally lower cost | Moderate premium | While S235 is cheaper initially, S355’s strength can lead to cost savings elsewhere. For critical marine applications, S355 is often the default minimum specification. |

S275 may be suitable for secondary, less weight-loaded elements in a marine environment. However, for primary structural elements in offshore platforms, wind turbine foundations, or ship hulls, S355 steel grades are almost always specified due to their superior strength-to-toughness balance.

Certifications and Standards for Offshore Steel

The marine and offshore sectors are governed by stringent global standards. Certifications are non-negotiable and provide the audit trail for material integrity. Key schemes include:

- EN 10204 Type 3.2 / 3.1 – Mandatory inspection documents providing verification of conformity.

- UKCA/CE Marking (EXC4) – For steels used in permanent offshore structures, EXC4 is the highest Execution Class, requiring strict control of material properties, traceability and factory production control.

- Project-Specific Approvals – Major operators and fabricators often have additional approval processes for steel mills and suppliers.

As an experienced supplier to the sector, Brown McFarlane’s Quality and Certification credentials are aligned with these demanding requirements, ensuring full traceability from mill to project site.

Applications of Offshore & Marine Steel

The right steel plate forms the backbone of:

- Fixed & Floating Oil & Gas Platforms

- Offshore Wind Turbine Foundations

- Shipbuilding & Vessel Conversion

- Portals, Cranes & Heavy Lift Equipment

- Bridges, Piers & Coastal Defence Systems

For Civil Engineering & Construction projects at the water’s edge, the principles of material selection merge marine and heavy structural demands.

In offshore and marine engineering, there is no margin for error. The choice of steel directly impacts a structure’s resilience, maintenance cost and service life. While grades like S355 serve as a reliable backbone, every project requires careful analysis of its specific environmental and load conditions.

Partner with a supplier that understands the depth of your project. With decades of experience, deep material expertise and the necessary certifications in place, Brown McFarlane is equipped to support your most demanding offshore and marine projects.

Ready to specify with confidence? Discuss your project requirements and explore our certified material stock.

Speak to our experts today to discover how we can help you with your project!