What is a Chromium Carbide Overlay Plate?

Chromium carbide overlay plates, such as ABRACLAD, are designed to deliver exceptional durability and versatility by combining a wear-resistant alloy overlay with a tough, weldable steel base.

These wear plates are engineered to provide outstanding resistance to abrasion, making them ideal for equipment subjected to harsh, high-wear environments. By using chromium carbide overlay plates, industries can significantly extend the service life of their machinery, even in some of the most demanding operating conditions, such as mining, construction and material handling.

More information

-

What is the Purpose of Chromium Plating?

Chromium carbide overlay plates are specifically engineered to minimise material loss and reduce component wear caused by abrasive materials, moderate impact or high-pressure environments.

By reducing wear and tear on critical components, these plates help heavy industries lower maintenance costs, prevent expensive repairs and avoid unplanned downtime that could disrupt operations.

They are an invaluable solution for industries aiming to ensure consistent, reliable productivity while enhancing the longevity of their equipment. Additionally, their adaptability allows them to be custom-fitted for a wide range of applications, making them a versatile and cost-effective choice for demanding industrial settings.

-

Benefits of ABRACLAD Wear Plate

- Extended Lifespan

ABRACLAD is specifically designed for durability in abrasive environments. Its high chrome alloy structure ensures a long service life, even under demanding conditions. - Reduced Downtime

Engineered for reliable performance under moderate to high impacts, ABRACLAD minimises maintenance interruptions, allowing for more efficient operations. - Customisable Fabrication

ABRACLAD plates offer exceptional flexibility. They can be bent, rolled, profiled, and fabricated into various shapes without compromising structural integrity. - Cost Effective Solution

With its balance of thickness and performance, ABRACLAD stands out as one of the most economical wear-resistant plates available, offering significant value over time. - Guaranteed Quality Assurance

Each ABRACLAD plate is EU-certified and accompanied by comprehensive quality test certificates, providing confidence in its reliable performance and compliance with industry standards.

- Extended Lifespan

-

Key Features

Base Plate Options

The standard base plate is S235JR, however, ABRACLAD wear plate can be applied to any weldable steel, including stainless steel and other grades, ensuring versatility across applications.

Special Alloys for Demanding Applications

- A62, A63, A64, A65: These high-performance grades are engineered for extreme environments, incorporating advanced materials such as silicon, niobium, tungsten, and molybdenum for superior performance.

- A60 SB: Lightweight plates manufactured using stringer bead technology are specifically designed for applications requiring significant bending flexibility.

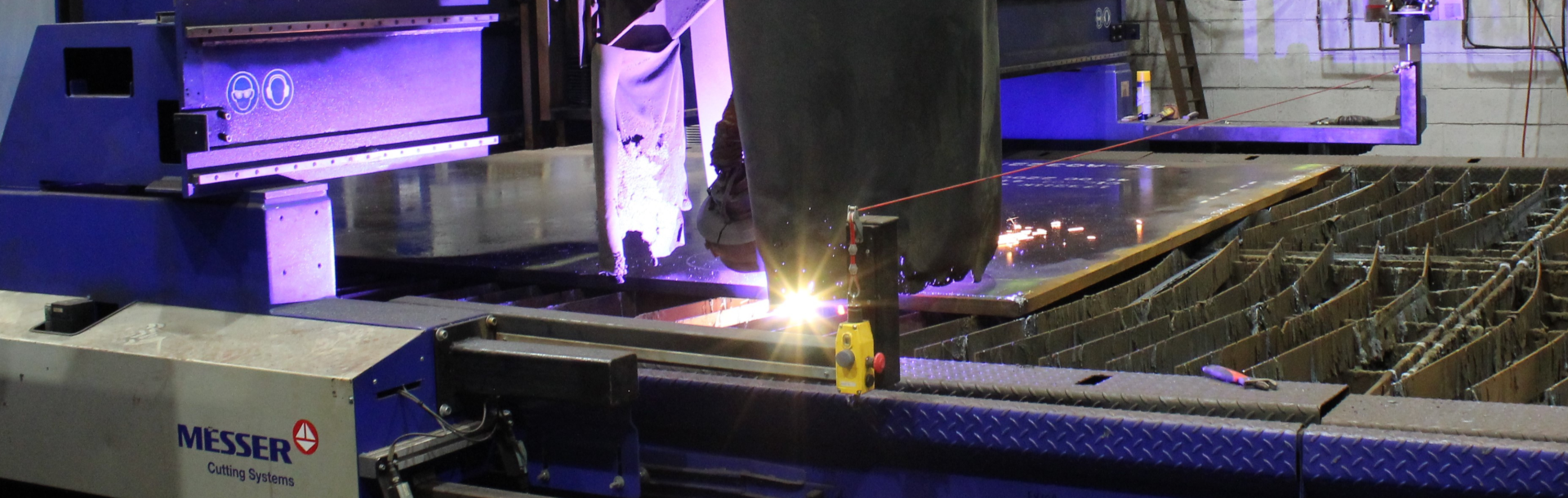

Fabrication Ready Steel Solutions

- Steel plates can be precisely plasma cut to include features such as holes, inserts or welded studs, ensuring seamless integration into your designs.

- Plates can also be bent, rolled, or fabricated without heat, making them ideal for pipes and standalone structures.

This comprehensive range of options ensures ABRACLAD products meet the highest standards of performance, adaptability and reliability for even the most challenging applications.

Applications

- Mining & Quarrying

- Cement Production

- Ports & Energy

- Steel & Manufacturing

- OEM Plant & Equipment