What is Weathering Steel?

Weathering steel, also known as low-alloy steel, is a group of steel alloys specifically formulated to develop a stable, protective rust layer when exposed to the elements. Unlike ordinary steel, where rust continuously flakes away, exposing fresh metal to further corrosion, weathering steel forms a dense, adherent patina that halts further atmospheric corrosion.

History and Development

The development of weathering steel dates back to the early 20th century, but it wasn’t commercialised until the 1930s by US Steel under the Cor-Ten trademark. Its use became prominent in the 1960s and 70s, notably in architectural landmarks and monumental sculptures, thanks to its aesthetic and durable qualities.

Common Industries and Use Cases

This steel is favoured in industries where longevity and minimal maintenance are critical. Key sectors include:

- Construction & Architecture – For building facades, structural frames and roofing.

- Civil Engineering – Bridges, gantries and transmission pylons.

- Transport – Railway wagons, shipping containers and heavy-duty vehicle components.

- Art & Sculpture – For large-scale outdoor artworks.

How Does Weathering Steel Resist Corrosion?

The secret to weathering steel’s corrosion resistance lies in its chemical composition. It contains small amounts of alloying elements, such as copper, chromium, nickel and phosphorus. When exposed to wet-dry cycles in the atmosphere, these elements promote the formation of a tight, oxide-based patina on the steel’s surface.

This patina develops over 1-3 years, evolving in colour from a bright orange to a deep, rich brownish-purple. Most importantly, this layer is impermeable to air and moisture, acting as a protective barrier that significantly slows the rate of further corrosion.

Benefits vs Traditional Coatings

- Self-Healing – The patina reforms if lightly scratched, unlike a painted coating which requires touch-ups.

- Zero Maintenance – Eliminates the need for repetitive and costly painting, sandblasting and recoating over a structure’s lifetime.

- Lower Lifecycle Cost – While the initial material cost is higher, the savings on maintenance make it far more cost-effective in the long run.

- Aesthetic Integrity – Architects and artists highly value the natural, evolving finish.

Weathering Steel Grades Explained

S355J2W Steel

S355J2W is a weather-resistant structural steel with excellent atmospheric corrosion resistance and toughness. The J2 indicates good impact performance at -20°C. Typically used for bridges, buildings, silos and pylons where durability and weather resistance are crucial.

S355K2W Steel

S355K2W is a high-toughness weathering steel designed for critical structures. The K2 ensures impact toughness at -20°C with higher notch toughness than J2 grades. Typically used for bridges, architectural facades, outdoor sculptures and offshore structures.

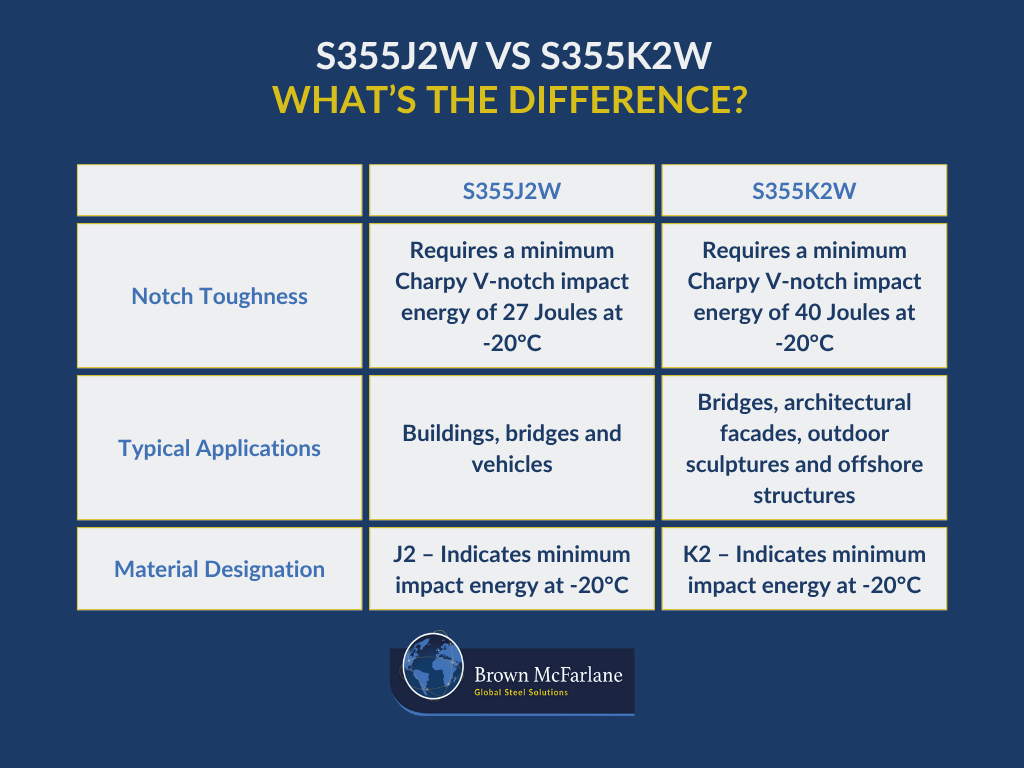

S355J2W vs S355K2W – What’s the Difference?

There are a few subtle differences between S355J2W and S355K2W.

Benefits of Weathering Steel in Construction

There are many benefits to using weathering steel for construction projects, including:

- Durability and Low Maintenance – Structures can last for decades with minimal intervention, as the protective patina eliminates the need for repainting.

- Sustainability Benefits – The long service life and elimination of paints contribute to a lower environmental footprint. It is also 100% recyclable.

- Cost-Effectiveness Over Lifecycle – The significant reduction in maintenance, inspection and repainting costs makes weathering steel a cost effective choice over the entire lifespan of a project.

- Aesthetic Appeal for Architects – The unique, rustic and ever-changing appearance provides a distinct visual character that is both natural and industrial.

Is Weathering Steel More Expensive Than Mild Steel?

Weathering steel typically has a higher upfront cost than standard mild steel, due to its specialised alloying elements.

However, the budget case is made over the entire lifecycle of the project. When you factor in the costs of surface preparation, multiple paint systems and recurring maintenance painting for mild steel over 20-30 years, weathering steel almost always proves to be the more cost-effective option.

Mild steel might still be used where:

- The structure is indoors and not exposed to the weather.

- The project has an extremely short design life.

- The initial budget is the primary constraint, with less consideration for long-term upkeep.

Common Applications of Weathering Steel

Because of weathering steel’s excellent structural integrity, strength and aesthetic patina, it lends itself to several different applications. Uses include:

Civil Engineering

Bridges, railway lines, architectural facades, sound barriers along motorways, transmission towers and retaining walls.

Transport

Shipping containers and heavy-duty mining vehicle bodies benefit from the material’s durability without the need for regular painting.

Offshore Structures

Used for non-immersed parts of platforms and wind turbines where salt spray resistance is vital.

Architectural Cladding & Sculptures

Its aesthetic appeal has been used to stunning effect in buildings like the Barclays Centre in Brooklyn and countless public art installations.

Choosing the Right Supplier for Weathering Steel

It’s essential to choose the right supplier for your weathering steel to ensure it not only looks great but also performs when it matters. Choose Brown Macfarlane weathering steel for:

- Superior Weather Resistance – Forms a protective rust-like layer to prevent future corrosion.

- A Cost-Effective Solution – No painting or regular maintenance needed, significantly reducing lifecycle costs.

- Environmentally Friendly Steel – Produced using less energy and fully recyclable, weathering steel is a sustainable choice for conscientious developers.

- The Aesthetic Appeal – Its natural patina changes subtly over time, making it a popular option for architectural and artistic applications.

- Versatility Across Applications – From structural bridges to outdoor sculptures, weathering steel’s adaptability suits diverse project needs.

At Brown McFarlane, we are a leading supplier of weathering steel with decades of expertise. We stock a comprehensive range of certified weathering steel grades, including S355J2W and S355K2W. Our team can provide technical guidance to ensure you select the right material for your project’s specific requirements, backed by our commitment to quality and service.